Tanami Gas Pipeline data integrity and materials traceability

Sentanil System’s Construction Management System (CMS) was a key tool used in the management of the pipeline Quality Assurance and Quality Control requirements of the recently completed 440 km Tanami Gas Pipeline in Northern Territory.

Newmont Mining Corporation engaged Australian Gas Infrastructure Group (AGIG) to build a gas pipeline to supply gas to its Granites and DBS mines, approximately 550km north-west of Alice Springs. This 440km pipeline follows the alignment of the Tanami Road, passing through a mix of pastoral land, Aboriginal freehold land and Crown land to connect the existing Amadeus Gas Pipeline to Newmont’s Tanami gold mines. It provides Newmont with the ability to use cost effective, reliable and cleaner gas fired power generation in place of existing diesel power generation.

AGIG contracted MPC Kinetic to construct the pipeline, which commenced early in June 2018, and was essentially completed by the end of December 2018. MPC Kinetic engaged Sentanil Systems for the use of the CMS system and associated support for the pipeline construction.

It was a challenging project due to the remoteness, associated limited communications infrastructure and the fast pace of construction. Two mainline crews working simultaneously usually a few hundred kilometres apart and the stringent MDR validation requirements following each hydro test section. Hence it was important to collect the right and relevant data in the field by the inspectors on the intelligent handheld data or scan units, using our data capture program. The program has recently been enhanced to enable intelligent lookups based on other linked lookups (eg. electrode batches and welding procedures) and also provides the ability of GPS data capture at the same time, if required.

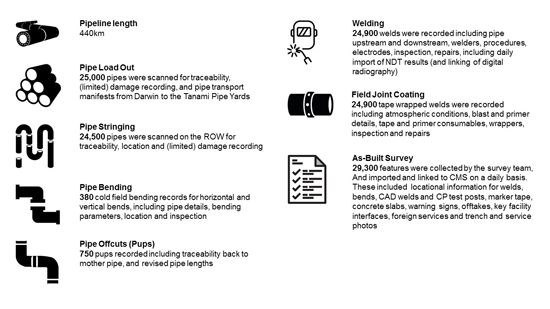

Key QA/QC activities and statistics

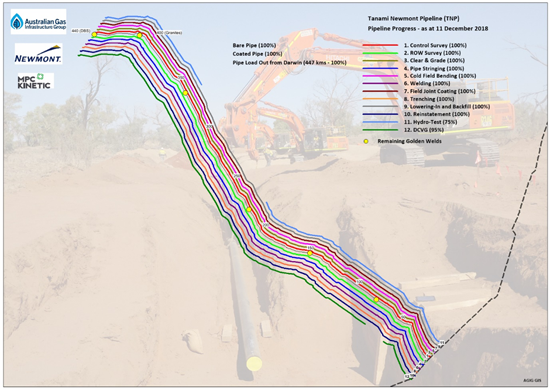

CMS was also used extensively to produce many of the MDR report requirements, which were subject to extensive third party validation immediately following completion of the 8 hydro test sections. CMS was used to produce the weekly progress ‘Rainbow’ charts.

CMS was also used extensively to produce many of the MDR report requirements, which were subject to extensive third party validation immediately following completion of the 8 hydro test sections. CMS was used to produce the weekly progress ‘Rainbow’ charts.

The CMS project data has been integrated with the survey and other locational related data, and uploaded into AGIG’s corporate X-Info Suite, GIS, Land Management, DBYD and AS2885 systems to provide ongoing support for the operations and maintenance phase of the pipeline.

The CMS project data has been integrated with the survey and other locational related data, and uploaded into AGIG’s corporate X-Info Suite, GIS, Land Management, DBYD and AS2885 systems to provide ongoing support for the operations and maintenance phase of the pipeline.

Sentanil would like to thank AGIG and MPC Kinetic for their valued support during all phases of this very successful project.

Sentanil is one of Mipela’s sister companies.

Popular Posts

A word from the BossAutomating the encroachment process

Kamapim end of year wrap-up

In Focus – tips and tricks

Product update

Security wrap-up for 2025

BYDA Utility Safety Conference

Staff update

Christmas trading hours

OLDER POSTS:

A Word from The Boss

Supporting Australia’s Renewable Energy Zones

Cultural Heritage and Community Responsibility: Insights from Barada Barna

Kamapim Update

Are Your Low Cost Digital Services Scrutinised?

InFocus

Product Update

Staff Update

A Word from The Boss

Security Update: AI in the Workplace – Hype, Hope and Hidden Risks

Multinet Gas Networks & X-Info Assurance suite: Mapping Out Another GE Smallworld success!

InFocus: Your Support Experience is Getting an Upgrade

Kamapim Update: Driving Continuous Improvement Across People, Product and Industry Insight

Product Update: X-Info Connect’s New Look!

Staff Update: Introducing Leo Liu

#projectMAD Team Update: 2025 Multiple Sclerosis (MS) Brissie to the Bay Fundraising Ride

A Word from The Boss

AGIG – Enhancing Landowner and Stakeholder Engagement

The Power of Real Time Data in the Energy and Infrastructure sector

Kamapim Update: An Unforgettable start to the year with Korrin Barrett

Assurance from a Telco’s perspective

Navigating the Complexities of Renewables Projects: A Smarter Approach to Stakeholder Management

Managing Landholder Relationships to Support Social License

The Power of Clean Data

Security update

A Word from The Boss

Gas Pipeline Victoria: Streamlining Right of Way Fault reporting

In Focus

GIS: Powering the Future of Energy with Mipela

Kamapim update

Staff Update: 21 Years of Being Awesome

Renewables Protection: Beyond Fences and Private Land

Streamlining Pipeline Patrol and Sightings Management

Product Update

Security update

Christmas trading hours

A Word from The Boss

Welcoming Inner West Council

In Focus: New Support Portal

Kamapim Update: Strategic Progress and Future Innovations

Staff Updates: Introducing…

Mipela Leads the Way in Sovereignty and Security

Christmas is coming…

Development Update: X-Info Connect version 8.0

Unlocking Innovation with AWS Serverless: A Proof of Concept

Epic Energy Powers Forward: Contributing to South Australia’s 2030 Renewable Energy Goals

Staying Ahead of Key Security Concerns for Asset Owners

A word from the Boss

Taking mobile data capture to another level

The importance of Multi-Factor Authentication

Product Update – X-Info Aware

Effective land management across the Gas Pipeline Victoria

It’s the stuff you don’t see that’s keeping you safe

Ampol joins our Client Community!

Ensuring Smoother User Management: Your Collaboration can Expedite the Process

SA Power Networks – Committed to Ensuring Security

Providing you that extra level of assurance

Do you have reporting fatigue?

Focus on the complex, the urgent and the sensitive

Making light work of Safety Management Studies

Safeguarding access and data integrity – the significance of using personal credentials to log onto software

Reporting Stakeholder Information to the Regulators

What integration with SPEAR means to Jemena

A truly epic project

The true power of data automation for Jemena

Tweed Shire Council using technology to deliver value to ratepayers

Using software to safely plant trees

How mapping retirement homes helps LendLease manage its 14,000 dwellings

Stakeholder management and a global wind energy company

ERA Water automates its asset protection with X-Info DBYD suite

ARTC implements X-Info DBYD suite as their automated response system

Beware the Spreadsheet

If you are breaking ground out in the field – we have you covered!

When community focus is key to the success of your project

How Gladstone Area Water Board saves time processing permits using X-Info DBYD suite

Mipela delivers more efficiencies to APA Group

Managing Cultural Heritage across Barada Barna land

Ever wondered how TransLink manage their Bus Stops?

Managing contaminated land compliance

Systematising pipeline risk management

Experience really counts when it comes to stakeholder management

City of Greater Dandenong implements DBYD automated response system

Stakeholder management – the answer is blowing in the wind

Flavour of the month – renewable energy projects

Automation in Remote Regions Delivers Multiple Benefits to Council

Powering through South Australia

There’s no watering down the importance of DBYD responses at Allwater

Tanami Gas Pipeline data integrity and materials traceability

Greater Shepparton City Council moves to X-Info DBYD suite

Putting your pipeline Safety Management Study information in one place

Making Lodging DBYDs Easier

Desktop GIS Analysis for Preliminary Route Selection

X-Info DBYD suite Perfect Fit for ATOM

First Gas Land Management

Managing Your Information

Managing Your Information – from beginning to end

The importance of data across the life of your assets

Mipela assist Luminous Energy in planning solar farms in Queensland

The Value of X-Info Plans Management – Zinfra

Real time data capture and reporting in remote field environment made possible with X-Info Aware

X-Info SMS suite – Safety Management Study

Property Information Service made easy

Your competitive advantage in field service management

Remote field task management and data capture providing results for real time consumption for Veolia

TGP optimises their field workforce with mobile data capture app

More than just maps… How do we add value to your GIS?

Automated back end processes provides Gladstone Area Water Board with improved responsiveness for issuing of permits

SEA Gas improves efficiency of land management

Perfect match: X-Info Connect and Maintenance Connection

News Archive

- Spring 2015

- Winter 2015

- Autumn 2016

- Winter 2016

- Spring 2016

- Summer 2016

- Winter 2017

- Spring 2017

- Summer 2017

- Autumn 2018

- Winter 2018

- Spring 2018

- Summer 2018

- Autumn 2019

- Winter 2019

- Spring 2019

- Summer 2019

- Autumn 2020

- Winter 2020

- Spring 2020

- Summer 2020

- Autumn 2021

- Winter 2021

- Spring 2021

- Summer 2021

- Autumn 2022

- Winter 2022

- Spring 2022

- Summer2022

- Autumn 2023

- Winter 2023

- Spring 2023

- Summer 2023

- Autumn 2024

- Winter 2024

- Spring 2024

- Summer 2024

- Autumn 2025

- Winter 2025

- Spring 2025

- Summer 2025

Tags

- Stories from our clients (56)

- A word from the boss (Hayden McDonald) (9)

- X-Info DBYD suite (9)

- Product news (9)

- X-Info Suite (9)

- X-Info Connect (8)

- X-Info Aware (6)

- Security updates (5)

- X-Info SMS suite (4)

- X-Info Plans Management (4)

- X-Info Stakeholder Management (4)

- GIS (3)

- Stakeholder management (2)

- Works Management module (2)

- X-Info Assurance suite (2)

- X-Info Service suite (1)

- X-Info WebConnect (1)

- X-Info Lands Management (1)